World-Class Machines

PTI PACIFIC is a 100% privately owned Australian engineering and original equipment manufacturer specialising in plant and process equipment for the beverage industry. Founded by beverage specialist and Managing Director, Lee Carty in 2014, PTI Pacific has quickly become one of Australia’s leading authorities in manufacturing novel beverage processing and plant equipment for wine, beer and beverage producers. The technical team at PTI Pacific is engineering and technology focused offering world-class solutions that enable wine, beer and beverage producers to increase output, lower costs and reduce their global environmental impact whilst ensuring increased profit, quality and repeatability.

PTI Pacific exports our technologies via our first-class partner and integrator network, with over 80 machines successfully installed in Australia, New Zealand and around the globe.

World-Class Engineering

PTI Pacific engineers, manufactures and commercialises turnkey machine solutions that meet genuine market needs. In addition to the creation of original novel machines, PTI Pacific offers OEM solutions to aid other companies develop and commercialise their own technologies as private label or contract manufacturing solutions. The solutions include dedicated project management systems and software as well as the latest engineering and design software including Inventor and Solidwork.

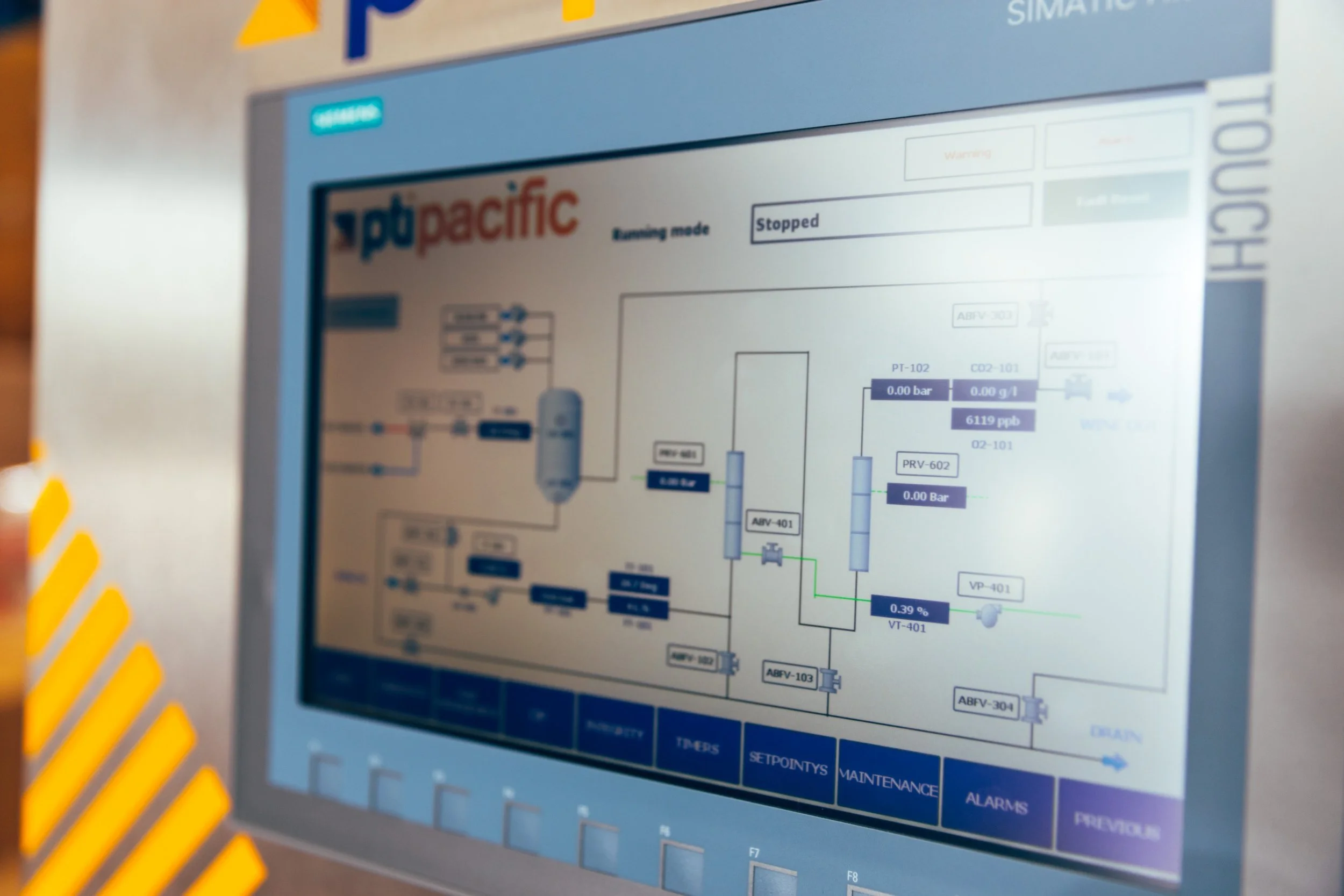

AUTOMATION & INTEGRATION

PTI Pacific offers customised programming, automation and electrical engineering solutions for a variety of industries and OEM products. The vast experience of electrical and mechanical engineering combined with the use of world-class Industry 4.0 technology solutions makes PTI Pacific the perfect choice for OEM products or factory automation, machine integration and electrical solutions.

100 SERIES

DEAERATED WATER

Key Features

✔ Ultra-Low Oxygen Levels: Achieves exceptionally low oxygen content for optimal product quality.

✔ Energy Efficiency: Uses minimal energy and gas, offering a cost-effective solution.

✔ Scalable Design: Modular and flexible to suit operations of any size, with easy expansion.

✔ Precision Monitoring: Real-time oxygen control with high-precision sensors for reliable performance.

✔ Compact and Hygienic: Skid-mounted, easy to install, and fully CIP-capable for sanitary production.

✔ Remote Monitoring: Online monitoring and reporting available.

The Cost-Effective and Reliable DAW Solution

Reduced CO₂ Waste | Fast Performance | Lowest Energy Costs

The 100 Series Deaerated Water Systems leverage cutting-edge membrane modules to deliver exceptionally low residual oxygen levels. Each module contains thousands of hydrophobic, gas-permeable hollow fiber membranes, creating an extensive internal surface area. This design maximises the contact area and time between water and gas, ensuring efficient oxygen removal.

With its modular design, the system is highly adaptable. It can be easily scaled to meet your capacity requirements by adding parallel membrane modules or achieving lower residual oxygen content with serial installations. Real-time oxygen monitoring is ensured by an optical O₂ sensor for perfect results every time.

FEATURES | BENEFITS | ADDITIONS

✔ All Stainless Steel Construction with premium components and electronics

✔ Hygienic Design with the highest quality engineering

✔ Onboard O₂ Monitoring & Control for precision performance

✔ No Heating Required for efficient operation

✔ No CO₂ Stripping for lower operational costs

✔ Seamless Integration with any upstream process

✔ Global Machine Support via 4G + Wi-Fi

✔ Remote Assistance Package for real-time troubleshooting

✔ Industry 4.0 Ready for advanced automation and connectivity

| Model | Flow Range (Litres/hour) | Average DO₂ Reduction | Optical O₂ Monitor | Integrated CIP | Remote Assistance |

|---|---|---|---|---|---|

| PTI-101 | 1000 L/hr - 5000 L/hr | 99% 72% |

Option | - | Option |

| PTI-102 | 1000 L/hr - 10,000 L/hr | 99% 95% |

Included | Option | Option |

| PTI-103 | 5000 L/hr - 10,000 L/hr | >99% 98% |

Included | Option | Option |

| PTI-104 | 10,000 L/hr - 50,000 L/hr | >99% >90% |

Included | Option | Included |

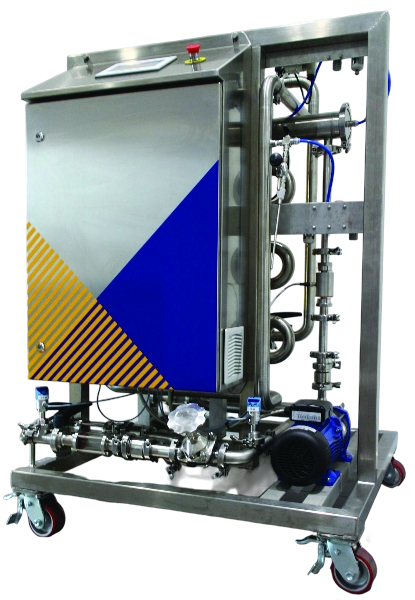

400 SERIES

CLASSIC CARBONATION

Key Features

✔ Economical inline carbonation solution for any beverage type

✔✔ Compact and portable

✔ Perfect for small craft producers or copackers

✔ Carbonation concentrations up to 8 g/L

✔ All stainless steel construction

✔ Integrated Optical CO₂ meter for precise carbonation and monitoring

The New Benchmark for Inline Carbonation

Precise Carbonation & Bubble Presentation I Reduced CO2 waste

The 400 Series Classic Carbonation technology offers the consistency and reliability needed for true inline carbonation of any beverages including sparkling wine, beer, carbonated soft drinks (CSD), water and functional beverages. Put an end to the re-work, extended time constant monitoring and wasted CO2 from static tank carbonation. The ultra-compact and simple machine satisfies entry-level startup manufacturers through to established beverages with inline carbonation flow requirements up to 10,000 litres per hour.

There’s no simpler solution than the Classic Carbonation range

FEATURES | BENEFITS | ADDITIONS

✔ Economic Class-leading Solution

✔ Hygienic Carbonation Pump + Drive

✔ Compact and Portable

✔ Automatic Butterfly Valves

✔ Onboard CO2 Monitoring & Control

✔ Hygienic design, highest quality engineering

✔ Integrated Outfeed Buffer Tank

✔ Turnkey – No machine integration needed

✔ Global machine support via 4G + Wi-Fi Remote Assistance Package

✔ Industry 4.0 Ready

| Model | Flow Range (Litres/hour) | Carbonation | Dimensions (mm) |

|---|---|---|---|

| PTI-401 | 200-2000 L/hr 50-530 gal/hr |

1.8 g/L 0.5-4 Vol |

700 x 1350 x 1900 |

| PTI-402 | 1000-5,000 L/hr 260-1320 gal/hr |

1.8 g/L 0.5-4 Vol |

700 x 1350 x 1900 |

| PTI-403 | 2000-8,000 L/hr 790-2100 gal/hr |

1.8 g/L 0.5-4 Vol |

1350 x 700 x 1900 |

| Standard Features | Optional Enhancements |

|---|---|

| Hygienic Feed Pump + VFD | Pump - Hygienic Double-Screw |

| Integrated CO2 Meter | Pump - Hygienic Lobe |

| Outfeed Buffer Tank + Level Control | Heat - Exchanger + Control |

| Automatic Butterfly Valves | Remote Assistance + Support |

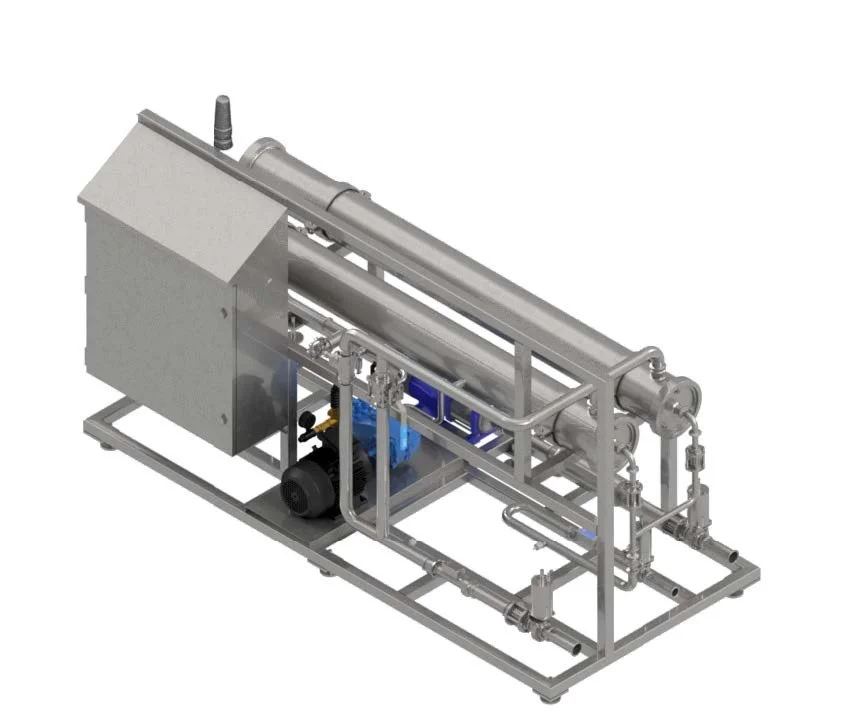

500 SERIES

MOLECULAR CARBONATION

Key Features

✔ The premium solution for inline carbonation

✔ Up to 33% less CO2 gas consumed compared to traditional inline or static tank carbonation

✔ Greater bead and bubble presentation, best suited to premium beverages e.g. sparkling wine. Increases bubble stability

✔ Precise carbonation up to 10 g/L or 5.1 Vol. CO2

✔ Increased filling efficiency and reduced foaming/fobbing with integrated degassing/deaeration module

✔ Inline carbonation at temperatures up to 18oC

✔ Optional Nitro dosing

The New Benchmark for Inline Carbonation

Precise Carbonation & Bubble Presentation I Reduced CO2 waste

The 500 Series Molecular Carbonation machines offer the unique membrane-based technology for the most efficient inline carbonation process on the market. Unique to PTI Pacific, this process involves sophisticated and precision measurement and dosing of CO2 gas into the flowing filtered beverage directly into a filling machine or buffer tank. The continuous inline CO2 measurement ensures that every litre is perfectly carbonated for the most consistent solution. PTI Pacific offers an unique integrated deaeration module which can increase filler speeds, reduce foaming and fill-height inconsistencies plus increase product shelf-life and flavour by reducing dissolved oxygen concentrations by up to 99.5%.

FEATURES | BENEFITS | ADDITIONS

✔ Unique Molecular Carbonation process offering bubble-free CO dosing/dissolving

✔ Hygienic design, highest quality engineering

✔ Ambient carbonation possible

✔ Increased shelf-life through low-DO2 deaeration module

✔ Turnkey solution, no machine integration needed

✔ Optional integrated CIP system with hygienic stainless-steel tank + chem. dosing

✔ Global machine support via 4G + Wi-Fi Remote Assistance Package

✔ Onboard CO2 Monitoring & Control

✔ Industry 4.0 Ready

| Standard Features | Optional Enhancements |

|---|---|

Hygienic Feed Pump + VFD Integrated CO2 Meter Outfeed Buffer Tank + Level Control Automatic Butterfly Valves Remote Assistance + Support |

Pump - Hygienic Double - Screw Pump - Hygienic Lobe Auto CIP with chem. dosing Optical Oxygen Meter Heat-Exchanger + Control Pre Filtration Final Filtration Drying System |

| Model | Flow Range (Litres/hour) | Carbonation | Dimensions (mm) |

|---|---|---|---|

| PTI-501 Carbonation Only |

200-2000 L/hr 50-530 gal/hr |

1-10 g/L 0.5-5.5 Vol. |

700 x 1350 x 1900 No CIP option |

| PTI-502 Carbonation + Degassing |

1000 – 5,000 L/hr 260 – 1320 gal/hr |

1-10 g/L 0.5-5.5 Vol. |

700 x 1350 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-503 Carbonation Only |

2000-8,000 L/hr 790-2100 gal/hr |

1-10 g/L 0.5-5.5 Vol. |

1350 x 700 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-504 Carbonation + Degassing |

2000-8,000 L/hr 790-2100 gal/hr |

1-10 g/L 0.5-5.5 Vol. |

1600 x 1200 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-505 Carbonation Only |

5000-15,000 L/hr 1320-4000 gal/hr |

1-10 g/L 0.5-5.5 Vol. |

1600 x 1200 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-506 Carbonation + Degassing |

5000-25,000 L/hr 1320-4000 gal/hr |

1-10 g/L 0.5-5.5 Vol. |

1600 x 1200 x 1900 1850 x 2000 x 1900 (CIP) |

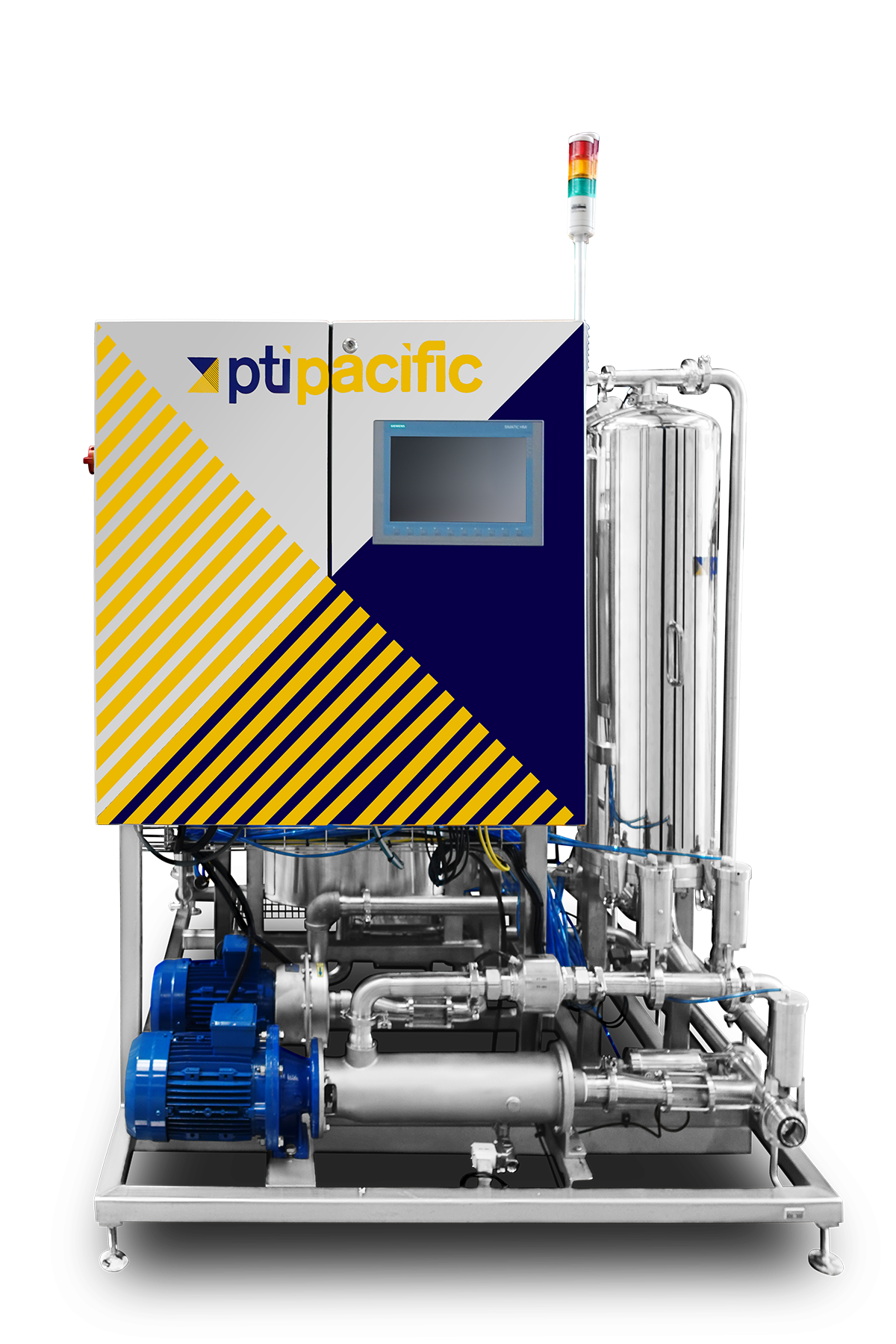

600 SERIES

WINE GAS MANAGEMENT

Key Features

✔ Inline Adjustment of Oxygen as low as 0.01 ppm

✔ Inline Increase/decreased of CO2

✔ Reduced Post-Ferment CO2 concentrations to get wines to market faster

✔ Up to 30% less CO2 gas consumed compared to traditional sparging

✔ Eliminate foaming issues during filling caused by Nitrogen sparging

✔ Increase filling line speeds by up to 15%

✔ Precision dosing of CO2 for ultimate consistency and palate freshness

✔ Variety of options and enhancements available

WINE GAS MANAGEMENT

The Unfair Advantage for Winemakers and Bottlers

The 600 Series Wine Gas Management technology enables winemakers and bottlers to free themselves of old-school methods of Oxygen (O2), Carbon Dioxide (CO2) and Nitrogen (N2) gas adjustment with a precise and automated machine. This state-of-the-art technology will rid winemakers and producers of inaccuracies and rework associated with adjustment of gases whilst increasing filling speeds and foaming caused by excess dissolved Nitrogen gas. Up to 10 - 15% of all sparging gas adjustments over or under-shoot the desired gas levels. Don’t waste resources, use 600 Series technology for reduced operating costs, increased quality and consistency.

ELIMINATE LABOREOUS CELLAR TANK SPARGING AND GAS- ADJUSTMENT REWORK I WINES TO BOTTLE FASTER I INCREASED FILLING SPEEDS AND REDUCED FOAMING I INLINE CO2 REDUCTION POST FERMENT I SIMULTANEOUS INLINE ADJUSTMENT OF CO2 AND O2 PRECISION CO2 ADJUSTMENT UP TO 99% REDUCTION OF DISSOLVED OXYGEN

FEATURES | BENEFITS | ADDITIONS

✔ Precise Wine CO2 and O2 Adjustment

✔ Precise Oxygen Reduction

✔ Greater shelf-life through low-DO2 Faster filling speeds

✔ Reduced foaming + fobbing at filling Robust + Hygienic Engineering

✔ Integrated Membrane Drying

✔ Static or Portable Turnkey Solution

✔ Precision or High-Flow Mode Options

✔ Optional Features + Enhancements

✔ Integrated CIP system + chem dosing Various Hygienic Feed Pump Options Conductivity Measurement

✔ Pre or Post Cartridge or Membrane Filtration

✔ Molecular Carbonation to 12g/L

✔ Global 4G + Wi-Fi Remote Assistance

✔ Onboard CO2 and O2 Monitoring Industry 4.0 Ready

| Model | Flow Range (Litres/hour) | Dimensions (mm) |

|---|---|---|

| PTI-601 | 500-5000 L/hr 130-1320 gal/hr |

700 x 1350 x 1900 No CIP option |

| PTI-602 Dual-Membrane | 500-10,000 L/hr 130-2640 gal/hr |

700 x 1350 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-603 | 1000-10,000 L/hr 265-2640 gal/hr |

1350 x 700 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-604 Dual-Membrane | 2000-20,000 L/hr 530-5283 gal/hr |

1600 x 1200 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-605 | 10,000-30,000 L/hr 2640-7925 gal/hr |

1600 x 1200 x 1900 1600 x 2000 x 1900 (CIP) |

| PTI-606 Dual-Membrane | 10,000-60,000 L/hr 2640-15,850 gal/hr |

1600 x 1200 x 1900 1850 x 2000 x 1900 (CIP) |

PTI - 606 SAMPLE VIDEO

700 SERIES

WINE ALCOHOL TUNING

Key Features

✔ Advanced Membrane Technology only removes alcohol from the wine

✔ Fine-Tune wine alcohol concentrations from by removing as little as 0.1% or as much as 8% v/v

✔ Optional water-saving batch process

✔ Can pass wine directly through the machine, no need for additional membrane filtration or separation processes

✔ Integrated water degassing to prevent wine oxidation

✔ Low pressure system is ultra-gentle on the wine

Wine Alcohol Tuning

Sweet Spot Wine Alcohol Concentrations

Fine tuning wine alcohol concentrations is becoming par for the course in modern winemaking. It’s well proven that wine balance can be achieved by fine adjustment or ‘Sweet Spotting’ of alcohol concentrations can increase the value of a wine. Not only this, the reduction in wine alcohol concentrations is being driven for other reasons including hot ripening seasons, climatic changes, consumer driven demand for lower alcohol or country-specific tax incentives. The addition of water to reduce alcohol concentrations is restricted or even illegal in many countries, but is also a poor substitute for true dealcoholisation due to the dilution of all flavours compounds. The 700 Series only reduces alcohol whilst leaving all of the flavours and aromatics for a premium fine tuning result.

Fine Tune Wine Alcohol for Flavour + Sweet-Spotting No Dilution of Flavours Manage Alcohols to Meet Export Domestic or Export Tax Rates Lower Alcohol Wines to Meet Changing Consumer Demands

FEATURES | BENEFITS | ADDITIONS

✔ Gentle reduction of alcohol via membrane process

✔ Process finished wine or wine permeate

✔ Continuous or batch processing

✔ Recover Alcohol Strip-Water for use with other wine-based beverages

✔ All stainless-steel construction with optional integrated CIP and membrane regeneration

✔ Fully automated with online alcohol measurement for piece of mind

✔ Premium Siemens Control System

✔ Remote assistance, monitoring and production reporting

✔ Optional wine and/or strip-water heating

| Model | Direct Wine Litres of Alc Removed (LAL) | Wine Permeate Litres of Alc Removed (LAL) | Integrated CIP | Density Meter | Inline Wine Heating (PHE) | Inline Strip-Water Heating (PHE) | Remote Assistance Package |

|---|---|---|---|---|---|---|---|

| PTI-701 | 10-20 LAL/hr | 20-50 LAL/hr | Option | Option | Option | Option | Option |

| PTI-702 | 20-50 LAL/hr | 50-100 LAL/hr | Option | Option | Option | Option | Option |

800 SERIES

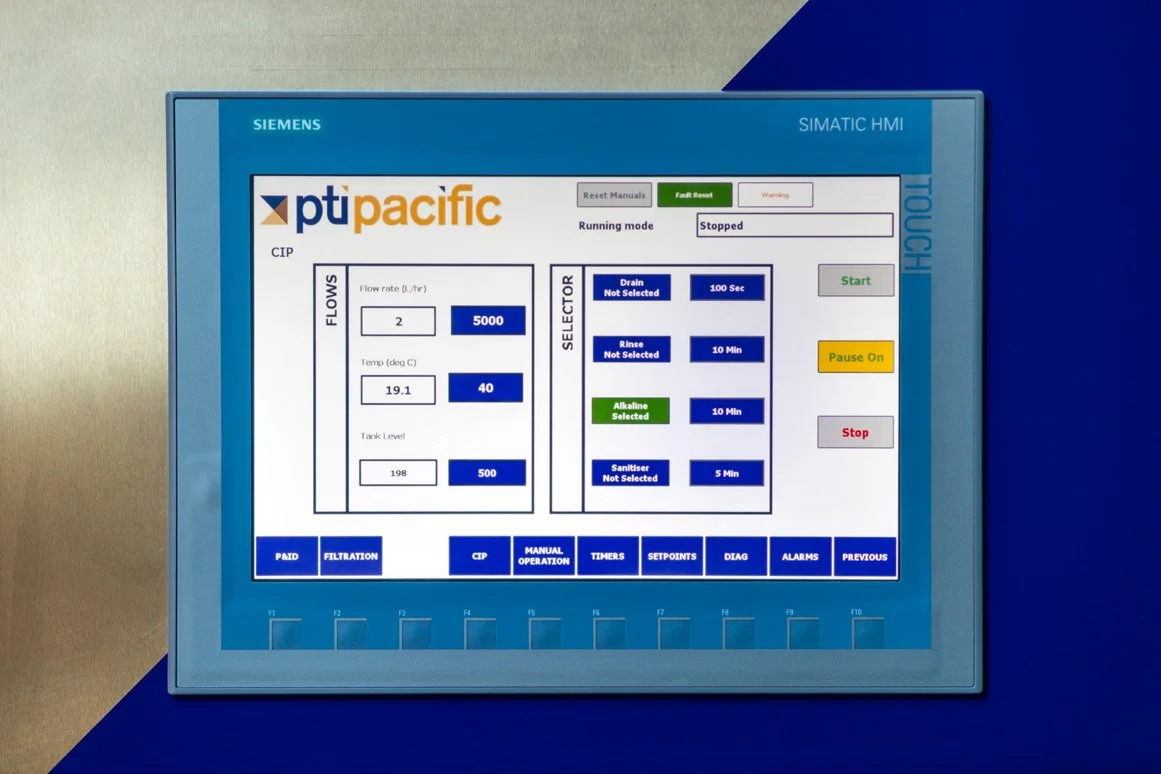

CLEAN-IN-PLACE SYSTEMS

Key Features

✔ Hygienic Design with all 316L Stainless Steel Construction

✔ Standard or customizable CIP recipes to suit any process requirement

✔ Single or Multiple Tank Configurations

✔ Integrated Chemical Dosing

✔ Individual Tank Level and Temperature Control

✔ Siemens Electronics

✔ Remote Assistance, Control and Monitoring

✔ Inline pH or Conductivity Measurement

✔ Optional gas, steam or electric heating

The Green Alternative for Beer, Wine & Beverage Filtration

Increased Quality I Reduced Energy and Waste

The 800 Series Clean-In-Place (CIP) Systems are designed to specific plant cleaning and sterilization applications, ensuring effective and efficient cleaning of tanks, process and packaging equipment. The 800 Series CIP systems are carefully sized and engineered to deliver optimal flow and pressure for thorough residue removal, effective rinsing, and reduced cycle times. These systems help lower operating costs while enhancing worker safety. The CIP systems are compliant with cGMP and ASME BPE standards.

FEATURES | BENEFITS | ADDITIONS

✔ Customizable Cleaning Programs Tailored cleaning cycles with adjustable time, temperature, and chemical concentration to suit specific beverage production needs.

✔ Automated Operation Fully automated process control reduces manual intervention, ensuring consistent and repeatable cleaning cycles.

✔ Remote Monitoring and Control Integrated with smart sensors and remote access capabilities, allowing real-time monitoring and control from anywhere.

✔ Energy and Water Efficiency Optimized cleaning cycles with reduced water, chemical, and energy consumption through precision dosing and intelligent resource management.

✔ Multi-Circuit Cleaning Capable of handling multiple cleaning circuits simultaneously, increasing facility productivity and minimizing downtime.

✔ Data Logging and Reporting Automated data recording of each CIP cycle for compliance reporting and traceability, ensuring regulatory requirements are met.

✔ Enhanced Safety Automated chemical handling systems reduce manual contact with hazardous substances, improving worker safety.

✔ Compact, Modular Design Scalable system configuration that integrates seamlessly into existing beverage processing facilities, with the flexibility to grow with production demands.

1000 SERIES WINE MEMBRANE CORRECTION

At PTI Pacific, we offer cutting-edge Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO) membrane systems, designed to give winemakers unparalleled control and precision in wine correction. Whether you are adjusting alcohol content, improving stability, or enhancing the purity of your wine, our advanced membrane technologies can help you craft exceptional wines with consistency and quality.

By integrating PTI Pacific’s advanced UF, NF, and RO membrane systems into your winemaking process, you can achieve greater control over your wine’s composition, enhance its quality, and address market challenges with precision. Our wine correction solutions help you create wines that meet your exact specifications, delivering excellence in every bottle.

Discover the future of winemaking with PTI Pacific – where technology meets tradition for superior wine crafting results.

ULTRAFILTRATION

✔ Removal of suspended solids

✔ Removal or reduction of proteins and larger macromolecules

✔ Clarification

✔ Decolourisation

✔ Tannin adjustment

✔ Wine clarification and microbial stabilisation

NANOFILTRATION

✔ Concentration and separation of tannin and polyphenols allowing fine-tuning of wines

✔ Partial dealcoholisation

✔ Water removal and flavor concentration

✔ Decolorisation

✔ Correction of faults such as Brettanomyces and Smoke Taint

REVERSE OSMOSIS

✔ Removal of volatile acidity

✔ Wine concentration

✔ Acid reduction

✔ Flavour Correction

✔ Correction of faults such as Brettanomyces and Smoke Taint

✔ Dealcoholisation

Benefits of Using UF, NF, and RO Membrane Systems in Winemaking:

Volatile Acidity Reduction

Correcting elevated volatile acidity is crucial for wine quality. Using RO, you can selectively reduce volatile acidity while retaining the essential components that contribute to the wine’s complexity, ensuring a clean and stable product.

Enhance Aroma and Flavour Intensity

Membrane systems allow you to concentrate specific wine fractions to enhance aromatic intensity and flavour richness, creating wines that stand out in a competitive market. This enables greater customisation and differentiation for premium and boutique wines.

Improved Wine Stability

Nanofiltration (NF) and Ultrafiltration (UF) membranes are highly effective for removing undesirable proteins, ensuring protein stability in your wines. This reduces the risk of haze or sediment formation, keeping your wines clear and visually appealing throughout their shelf life.

Minimise Product Loss

Compared to traditional correction methods, UF, NF, and RO membranes enable more efficient separation with minimal wine loss, preserving more of your valuable product during the correction process.

Precision Alcohol Adjustment

Our Reverse Osmosis (RO) systems allow for precise removal of alcohol without compromising the delicate flavour balance. This technology ensures you can create wines with ideal alcohol levels to meet market demands and regional preferences.

Selective Taint Removal

From smoke taint to Brettanomyces contamination, membrane filtration offers a targeted solution. RO and NF membranes can selectively remove unwanted taints while preserving the wine’s core characteristics, giving you control over even the most challenging winemaking conditions.

Color and Tannin Management

Ultrafiltration (UF) membranes enable the removal of unwanted color compounds and excess tannins while preserving desirable phenolic qualities. This technology helps refine your wine’s visual appeal and mouthfeel for a more balanced and elegant product.

1300 SERIES

PRECISION FILTRATION

The Crossflow Killer

Key Features

✔ Turnkey filtration system suited to premium products such as beer and wine

✔ High-surface area filters designed to last 12-24 months

✔ Automatic backwashing of cartridges with high-velocity water

✔ Filter porosities from 20 μm – 0.45 μm absolute

✔ Up to 20% reduction in energy costs

✔ Reduced water consumption

✔ Oxygen-Free Filtration for sensitive products

✔ Ultra-gentle filtration – no shearing

✔ No product recirculation or over-processing

✔ Zero product losses

✔ No heating of product during filtration

✔ Cost effective alternative to centrifuge or crossflow filtration

The Green Alternative for Beer, Wine & Beverage Filtration

Increased Quality I Reduced Energy and Waste

The new 1300 Series Automatic Filtration technology ensures that there is no adverse affect the body, aroma or taste of your wine, beer or premium beverages. The fully closed system with inert gas-purging prevents oxidation, can be cleaned, sterilised and the internal pleated filter can be re-use to keep operational costs and landfill to a minimum. The machine is used for clarification, fine filtration right up to total retention of micro-organisms if required. Each product provides high throughput with 100% error-free operation. Safe, reliable and accurate, the 1300 Series’ range offers smart design and engineering with manual, semi-automatic or automated systems available. Remove fermentation by-products that negatively impact flavor and odour, plus avoid damaging thermal treatments when removing spoilage organisms with the compact, low maintenance and cost-effective machine whilst minimise waste, water and utilities consumption.

The world’s most gentle, economical and energy efficient automatic filtration solution

FEATURES & BENEFITS

✔ High surface area filters for maximum possible filter life and simple cleaning and re-use

✔ Filter life up to 3 years from installation

✔ No loss of product

✔ No oxidation

✔ Re-usable cartridge technology

✔ Uses less water

✔ Uses less energy

✔ Low maintenance costs

✔ Less landfill and disposal costs

✔ Hot water sterilisable

✔ Wide-chemical compatibility

OPTIONS AND ADDITIONAL ITEMS:

✔ Semi-Automatic or Fully Automatic machine range

✔ Single or dual-stage filtration process with porosities from 0.45, 0.65, 1.2, 3.0, 5.0, 8.0 and 20 μm

✔ Process flow rates from 3,000-30,000 litres/hr filtration with automatic cleaning

✔ No need for potentially dangerous processing aids such as perlite or kieselguhr

✔ Hygienic design

✔ Packed with features including remote assistance and operation

1400 SERIES

MOLECULAR CARBONATION + COUNTER PRESSURE FILLING

Key Features

✔ Molecular carbonation module for premium and precise carbonation

✔ Inbuilt pump with speed adjustment

✔ 1 μm, 0.5 μm, 0.45 μm (PES) and 0.2 μm (PES) Pre-filtration module

✔ Integrated Counter-Pressure bottle filler

✔ Adjustable carbonation level from 2-10 g/L CO2

✔ Light-weight design

✔ Removable stainless steel drip tray

✔ Pneumatic bottle lifting

✔ Perfect for samples & New Product Development (NPD)

✔ No electricity required for excellent portability

Single Bottle Molecular Carbonation Device and Counter-Pressure Filling

The 1400 Series Molecular Carbonator with integrated bottle filler is the perfect tool Suitable for small production, trade samples and New Product Development (NPD). Using PTI Pacific’s unique Molecular Carbonation method for a premium and adjustable CO2 concentrations for precise and repeatable sampling. CO2 levels can be simply adjusted by increasing or decreasing the gas pressure to concentrations as high as 10 g/L CO2.

The robust bench-top design allows for installation in any laboratory or production area and requires no electrical power. The fully contained device includes:

All stainless-steel Construction, Counter-Pressure Filling + Inline Carbonation, Adjustable CO2 Concentration up to 10g/L, Can Fill any Glass or PET Bottle Format or Size Up 1 Litre

FEATURES & BENEFITS

✔ Stainless steel counter-pressure filling head suitable for bottles and cans

✔ Integrated Inline Molecular Carbonation

✔ Adjustable Carbonation levels from 2-10 g/L

✔ Stainless steel construction

✔ Integrated filling/carbonation pump

✔ Manual filling operation

✔ Suitable for a large variety of glass and can bottle sizes + formats

✔ Protective Perspex screen door

✔ 8 litre BPA-Free sampling and CIP container

OPTIONS AND ADDITIONAL ITEMS:

✔ Premium Inline filtration capsule range from 1.0 and 0.5 μm PP microfiltration or 0.45 and 0.22 μm PES membrane capsules

✔ Pneumatic bottle lifting

✔ Cleaning and sanitisation chemicals

✔ Additional 8 litre sampling and CIP containers

✔ Dimensions: 460 mm x 560 mm x 880 mm (L x W x H), Total weight 32 kg