Brewing & Spirits

PTI Pacific is a 100% Australian owned company specialising in the design, engineering and manufacturing of high-quality machines that solve genuine industry and process problems including:

Molecular Carbonation - The game-changing method of inline carbonation of premium filtered beverages using PTI Pacific’s exclusive membrane system for carbonating whilst simultaneously degassing/deaerating.

Classic Carbonation - Conventional but highly effective inline carbonation of beverages, suits any style of beer or beverage including cloudy and pulpy products with a variety of flow rates

Deaerated Water - The most economical and reliable method of deaeration of water without wasting CO2 gas or tying up tanks with old-school deaeration methods. A single pass can achieve < 10 ppb O2 water, ready for push-through or cutting back high-gravity beers.

Automated Filtration - The crossflow killer has arrived. PTI Pacific offers the most gentle automated and self-cleaning filtration system on the market. It’s a perfect solution to more aggressive cross-flow filtration systems with no dissolved pickup or colour/flavour losses through adsorption. This is the perfect craft beer filter

CIP Solutions - Economical CIP solutions for cellar and packaging

NPD Filling - PTI Pacific’s latest invention is the bench-top carbonator and bottle filler for carbonated products and sampling. Carbonate and fill a single bottle up to 10g/L CO2 with this compact device

Our Most Popular Technologies for Brewers & Distillers

100 Series - Deaerated Water

400 Series - Classic Carbonation

1300 Series - The Crossflow Killer

1400 Series - Benchtop Carbonator/Filler

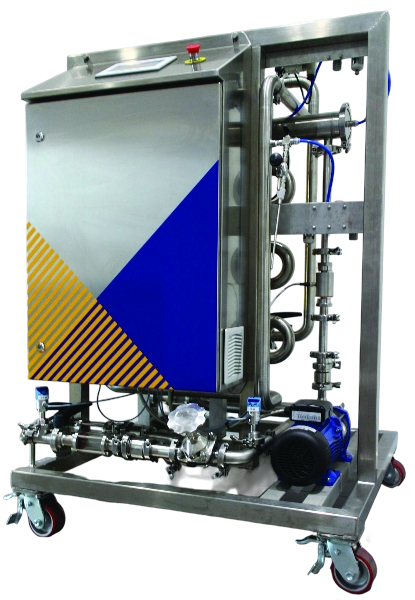

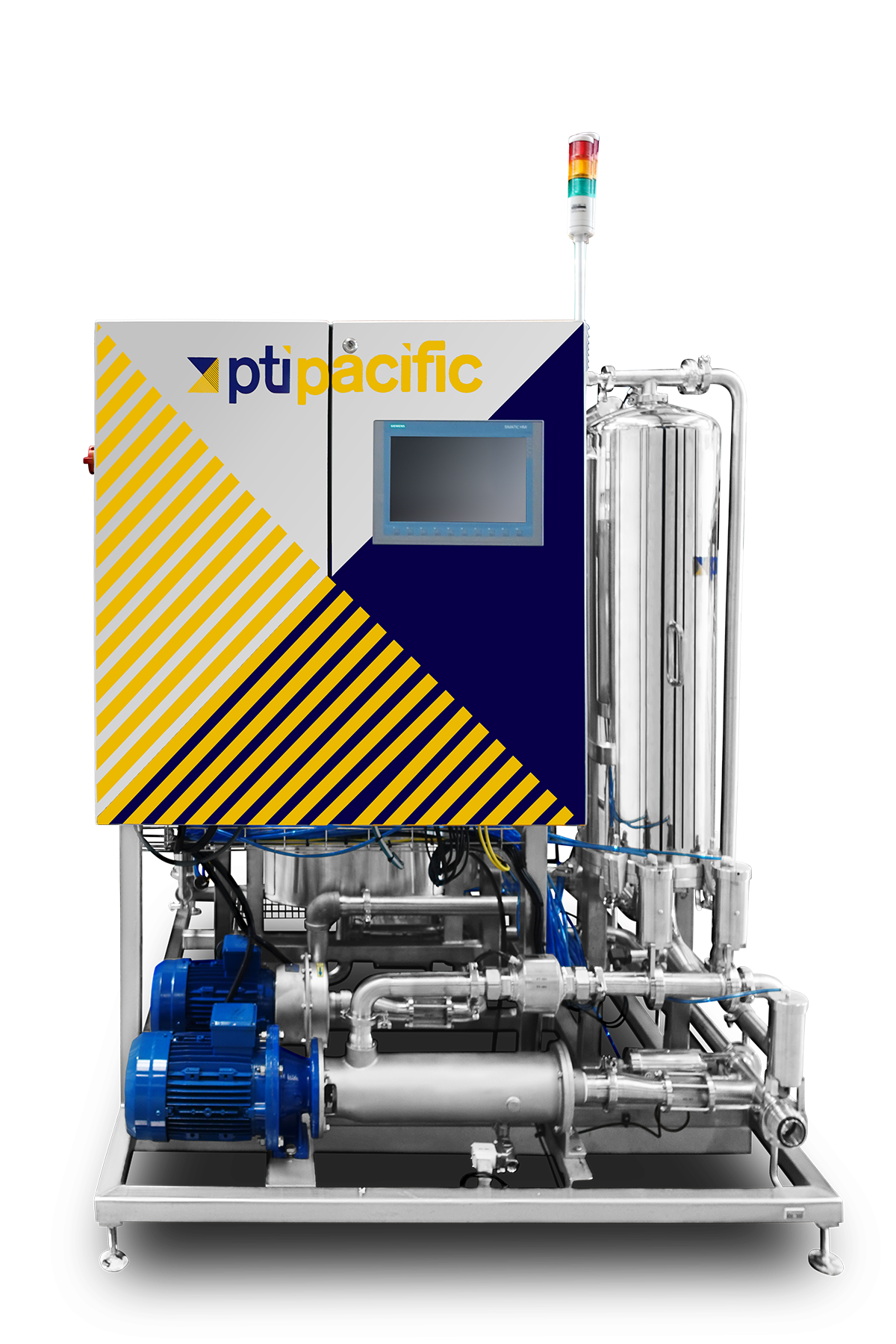

400 Series - Classic Carbonation

Classic Carbonation

For unfiltered beverages such as juices, cold-brew coffee or some craft beer styles we recommend the Classic Carbonation method which is uses a traditional CO2 dosing system rather than a membrane cells used in the 500 Series range. Our high-quality automation ensures the most accurate dosing and dissolving of the CO2 gas as the desired concentration. Perfect for batch processing or integration with new or existing filling equipment.

This automated machine is suitable for producers who chose not to filter their product or who want an economical method of inline carbonation.

Wine, Cider, Beer, Soft drinks, Water

Integrates with bottling & canning machines

Precise CO2 dosing

Reduced costs and increased efficiency compared to static tank carbonation

Inline Carbonation from 1 - 8g/L CO2

Optional inline nitrogenation available

Optional integrated inline Degassing/Deaeration

Premium Siemens electronics

Various Carbonation Pump options

All stainless steel construction

| Model | Flow Range (Litres/hr) | Carbonation | Integrated CIP | CO2 Monitor | Optical O2 Monitor | Feed Pump |

|---|---|---|---|---|---|---|

| PTI-401 | 500 – 2,000 | 1 - 8g/L C02 | Option | Included | Option | Sanitary Centrifugal |

| PTI-402 | 1000 – 5,000 | 1 - 8g/L C02 | Option | Included | Option | Sanitary Centrifugal |

| PTI-403 | 3000 – 10,000 | 1 - 8g/L C02 | Option | Included | Option | Sanitary Centrifugal |

500 Series - Molecular Carbonation for Sparkling Wine & Premium Beverages

Unique to PTI PACIFIC, Molecular Carbonation this is the holy-grail of carbonation for high-quality beverages. The process involved using an hydrophobic membrane cell combined with precise automation and dosing methods to produce the most consistent and reliable carbonation process available today.

This method is perfect for all styles of filtered sparkling wine, beer, juice, soft-drinks and water. The result is the most consistent carbonation with a premium bubble finish, long-lasting bead and excellent mouthfeel.

Machines are suited to Premium Beverages such as Wine, Cider, Beer, Soft-drinks and Water

Precision, Bubble-free CO2 dosing

Carbonation from 1 – 10 g/L CO2

Premium Bubble & Bead presentation

Integrated Degassing/Deaeration (option)

Inline cooling and temperature management

Optional integrated degassing/deaeration function allows for the control and management of dissolved gases prior to carbonation. Reduction in dissolved nitrogen and oxygen is essential for all water-based products such as seltzer, mixers etc. This degassing also significantly benefits carbonation by maximising filling speeds by reducing foaming and fobbing, increasing shelf-life and maximising carbonation CO2 concentrations.

500 Series machines can be integrated with any counter-pressure bottle, can or keg-filling machines.

| Model | Flow Range (Litres/hr) | Integrated Degassing | CO₂ Monitor | Pre-Filter | Sanitary Pump | Actuated Valves | Magnetic Flow Meter | CIP | Auto Temp. Control | WiFi Assistance | Recipe Function |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PTI-501 | 500 – 1,500 | NA | Option | Option | ✔ | ✔ | ✔ | Option | Option | ✔ | ✔ |

| PTI-502 | 1,000 – 3,000 | Option | Option | Option | ✔ | ✔ | ✔ | Option | Option | ✔ | ✔ |

| PTI-503 | 1,500 – 5,000 | NA | ✔ | Option | ✔ | ✔ | ✔ | Option | Option | ✔ | ✔ |

| PTI-504 | 2,000 – 9,000 | Option | ✔ | Option | ✔ | ✔ | ✔ | Option | Option | ✔ | ✔ |

| PTI-505 | 9,000 – 20,000 | NA | ✔ | Option | ✔ | ✔ | ✔ | Option | Option | ✔ | ✔ |

| PTI-506 | 10,000 – 40,000 | Option | ✔ | Option | ✔ | ✔ | ✔ | Option | Option | ✔ | ✔ |

100 Series - Deaerated Water Systems

Enhancing Quality with Deaerated Water in Brewing & Spirits Production

Deaerated water is a critical component in brewing and spirits manufacturing, ensuring flavor consistency, stability, and extended shelf life. The presence of dissolved oxygen can cause oxidation, leading to off-flavors, discoloration, and reduced product quality. By using high-purity deaerated water, brewers and distillers can preserve the integrity of their beverages while maintaining a superior taste profile.

Advanced Membrane Deaeration for Precision & Purity

Our membrane deaeration systems provide an efficient and reliable solution for removing dissolved oxygen from water. Utilizing advanced membrane technology, these systems selectively strip oxygen, ensuring high purity and oxidation prevention. The result is exceptional water quality, safeguarding the taste, aroma, and shelf life of the final product—essential for brewers and distillers demanding consistency and excellence.

Our Deaeration Solutions

PTI-101A: Compact Deaeration & Carbonation System

A versatile all-in-one solution for small breweries and beverage producers, combining water/product deaeration and precise tank carbonation in a single unit.

✔ Dual Functionality – Eliminates oxygen and enables precise carbonation.

✔ Optimized for Small Producers – Ideal for small-scale operations.

✔ Enhanced Product Control – Prevents oxidation while ensuring consistency.

PTI-102: Precision Deaeration for Small-Scale Production

✔ Flow Range: 500 – 5,000 L/hr

✔ Oxygen Reduction: < 5 ppb

PTI-104: High-Efficiency Deaeration for Mid-Sized Operations

✔ Flow Range: 5,000 – 20,000 L/hr

✔ Oxygen Reduction: < 5 ppb

PTI-106: Large-Scale Deaeration for Industrial Production

✔ Flow Range: 20,000 – 50,000 L/hr

✔ Oxygen Reduction: < 10 ppb

Achieve Unparalleled Product Quality

Ensure superior flavor stability, consistency, and extended shelf life with PTI Pacific’s membrane deaeration technology. Contact us today to discuss how our solutions can integrate seamlessly into your production process.

800 Series - Automated Clean-in-Place (CIP)

Designed and manufactured by PTI Pacific, the 800 Series CIP System sets a new standard in automation, hygiene, and efficiency for the food and beverage industry. Engineered to ensure optimal cleanliness with minimal downtime, this system features automatic chemical dosing for precise and effective sanitation.

Modular options such as an integrated steam boiler and heat exchanger enhance the cleaning process, providing hot water sterilization for process equipment and filling systems.

800 Series CIP Models

✔ Eco-CIP – A portable, single or dual-tank system with semi-automatic operation via a Siemens control system. Ideal for small-to-medium wineries, breweries, and packaging facilities that require efficient but flexible CIP solutions.

✔ Maxi-CIP – A fully automated, high-capacity CIP solution designed for large-scale producers. Available in 2 to 4-tank configurations, with tank volumes up to 2000L, ensuring repeatable and integrated CIP processes.

Key Features & Options

✔ Integrated steam boiler & heat exchanger – Instant hot water production & sterilization

✔ Automatic valves with feedback – Ensuring precise automation

✔ Recipe functions & remote monitoring – Programmable cleaning cycles with online support

✔ Seamless process integration – Tailored solutions to integrate Maxi-CIP into your existing system

For more details or to discuss integration, contact our team today.

1000 Series - Wine Membrane Separation Systems

Membrane systems have revolutionised modern winemaking, offering precise and efficient solutions for refining wine composition and quality. These advanced technologies, including ultrafiltration, nanofiltration, and reverse osmosis, enable winemakers to selectively manage components such as alcohol, acidity, and phenolics while preserving the wine’s natural characteristics. By providing unparalleled control over the winemaking process, membrane systems help produce cleaner, more balanced wines that meet specific stylistic and market demands. Whether for clarification, stabilisation, or adjustment of key wine parameters, membrane systems are an essential tool in the production of high-quality wines.

Ultrafiltration

Ultrafiltration is a cutting-edge technique in winemaking that enhances the quality and stability of wines by selectively removing unwanted particles and microorganisms. This process helps in clarifying wines, reducing microbial loads, and improving shelf life without compromising flavour or aroma. The ultrafiltration process is highly effective in maintaining the wine's natural characteristics, making it an essential tool for producing cleaner, more refined wines. Whether for clarification, microbial stabilisation, or the removal of haze-forming components, ultrafiltration offers a precise and efficient solution tailored to modern winemaking needs.

Wine Clarification: Removes suspended particles and haze, resulting in clear, bright wines.

Microbial Stabilisation: Reduces microbial loads, enhancing wine stability and shelf life

Tannin and Protein Management: Controls tannin and protein levels to prevent haze formation.

Flavour Preservation: Retains natural flavours and aromas during filtration.

Colour Adjustment: Assists in achieving the desired wine colour by selective filtration.

Nanofiltration

Nanofiltration is an advanced technology used in winemaking to selectively separate and concentrate specific components of the wine. This process is particularly useful for adjusting wine composition, such as reducing alcohol content or concentrating desirable compounds like phenolics and aromas. Nanofiltration allows winemakers to fine-tune the balance of the wine, enhancing its overall quality while preserving its natural character. With precise control over molecular separation, nanofiltration is a powerful tool for creating wines that meet specific stylistic goals and market demands.

Alcohol Reduction: Selectively reduces alcohol content while maintaining flavour and aroma

Concentration of Phenolics and Aromas: Enhances the intensity of desirable wine components

Acid Adjustment: Balances acid levels to achieve desired wine profiles

Colour Enhancement: Concentrates pigments to deepen wine colour

Selective Removal of Undesirable Compounds: Eliminates specific unwanted molecules without affecting overall wine quality

Reverse Osmosis

Reverse osmosis is a highly effective technique in winemaking that allows for the precise manipulation of wine composition. By applying pressure to the wine through a semi-permeable membrane, reverse osmosis separates water, alcohol, and other small molecules from the wine, enabling winemakers to concentrate flavours, reduce alcohol content, and manage volatile acidity. This process is invaluable for correcting wine faults, enhancing specific attributes, and creating balanced, high-quality wines that meet precise stylistic goals. Reverse osmosis is a versatile and powerful tool for modern winemaking, offering unparalleled control over wine composition.

Alcohol Reduction: Lowers alcohol content without compromising flavour and aroma

Volatile Acidity Reduction: Corrects high levels of volatile acidity to improve wine stability and quality

Concentration of Flavours: Enhances the intensity of flavours and aromas by removing excess water

Wine Fault Correction: Removes specific undesirable compounds to rectify wine faults

Water Addition Management: Adjusts water levels to balance wine concentration and volume

PTI-1400 Series: Benchtop Carbonation & Filling for NPD

The PTI-1400 Series is the ultimate solution for benchtop carbonation and filling, designed for New Product Development (NPD) and sample preparation. Create presentation-ready carbonated beverage samples in minutes with this compact, user-friendly system.

✔ Rapid Sample Production – Perfect for testing flavor variations with as little as 1 liter of product

✔ Versatile Carbonation Control – Easily adjust carbonation levels with a simple dial, from a light spritz to high carbonation

✔ On-Demand Sampling – Sales reps can prepare small batches for customer tastings in minutes

Key Features

✔ Molecular Carbonation Module – Ensures precise and premium carbonation

✔ Integrated Counter-Pressure Bottle Filler – For consistent results with low dissolved oxygen pickup

✔ Adjustable Carbonation (2–10 g/L CO₂) – Fine-tune carbonation to match product requirements

✔ Built-in Pump with Speed & Pressure Control – Allows for customized operation

✔ Optional Pre-Filtration Modules – Available in 1.0-micron or 0.45-micron sterile options (other sizes available)

✔ Compact, Portable Design – No electricity required for maximum flexibility

✔ Bottle Pre-Gassing & Counter-Pressure Filling – For optimal carbonation and product stability

✔ User-Friendly Operation – Simple setup and easy adjustments for quick, efficient use

The PTI-1400 Series is the perfect NPD tool for beverage manufacturers looking to refine flavors, test carbonation levels, and create high-quality samples on demand.

Contact us today to learn how the PTI-1400 Series can enhance your product development process!

1500 Series - Automatic Cartridge Filtration

The 1500 Series Automated filtration system combines traditional cartridge or lenticular filtration technologies for bespoke automated solutions. Constructed in all stainless steel, the 1500 Series bespoke filtration systems include a variety of options such as:

Suitable for lenticular and/or cartridges

Variety of valve options and manufacturers

Siemens PLC and HMI with remote assistance and support

Integrated CIP and cartridge backwashing (where applicable)

Automatic membrane integrity testing

Filter housing lifting device

Various feed pump options

Process Filtration Specialists

With over 30 years of combined process filtration experience, PTI Pacific is your best partner for everything winery filtration. From water filtration including media, carbon and membrane systems, to CIP recovery and ultra-pure water production, PTI Pacific can offer the perfect and most economical solution.

Water Filtration including Carbon, Media

Membrane systems for water and CIP recovery - MF, UF, NF, RO

Sartorius 12-inch and 16-inch Lenticular Filter Modules

Sartorius 400x400 and 600x600 Filter Sheets

Sartorius Premium Pleated Cartridges, Membrane and Capsule Filters

Integrity Testing Devices

Australia’s Largest Range of Stainless Steel Housings

Sartorius JumboStar

The Most Gentle and Environmentally Friendly Method of Filtration for Wine

JumboStar by Sartorius has unique pleating technology allows a large filtration area for a high-flow rate and large retention capacity. Each pleat has a different length to allow more efficient back-flushing compared to standard filter cartridges.

Features include:

High filtration area 28 m2 (40” length)

High filtration capacity

High flow rate

The internal diameter of the cartridge of DN 100

The robust housing design can withstand significantly higher flow rates when back-flushing compared to standard cartridges

High resistance to differential pressure up to 4 bar | 58 psi at 20°C (68°F)

High temperature resistance (steam sterilisable)

Wide chemical compatibility for Jumbo Star filters

Brewery, Packaging Automation & Mechanical Engineering

PTI Pacific has extensive experience in wine production through to bottling and packaging and as such are the perfect partner for your electrical and automation upgrades or projects. Whether it’s control

PLC and HMI Programming

Control Panel Building and Installation

Electrical drafting and design

Machine upgrades and automation

Automation and Controls for Pumps, Drives, Valves, Heat-Exchanger, Conveyors etc

Tank Temperature Control Systems

Remote Machine Assess and Telemetry

SCADA Programming and Development

In addition to Electrical and Automation, PTI Pacific can offer a suite of mechanical and project engineering solutions for any winery application. These include:

Machine and factory design, layouts, P&ID and process flow modelling

CAD design including Autocad and Solidworks 2D/3D modelling

Project management for new or upgrade process and packaging lines

Machine sourcing and procurement including importing, installation and commissioning

SOP and operations manual development and writing

Service and preventative maintenance support