Cosmetics

Optimized Solutions for Cosmetic Manufacturing

PTI Pacific, a 100% Australian-owned company, provides high-quality machinery and production solutions tailored for the cosmetics industry.

CIP Technologies – Cost-effective automated Cleaning-in-Place (CIP) systems, from mobile single-tank units to multi-vessel hot water and steam sterilization for small and medium facilities.

Deaerated Water & Gas Management – Advanced solutions for removing dissolved gases in water and cosmetic formulations, ensuring product stability and quality.

Process Filtration & Membrane Separation – Precision filtration and membrane separation technologies, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, for water and cosmetic product refinement.

Talk to us today about our specialist team today about how we can help optimise your production or packaging processes. Contact Us

Our Most Popular Technologies for Cosmetics Manufacturers

800 Series – Advanced Solutions for Cosmetic Manufacturing

PTI Pacific’s 800 Series delivers high-quality, precision-engineered solutions for cosmetic production, ensuring efficiency, product stability, and compliance with industry standards.

CIP Technologies – Cost-effective Cleaning-in-Place (CIP) systems, from mobile single-tank units to multi-vessel hot water and steam sterilization, ideal for small and medium-sized cosmetic facilities.

Deaerated Water & Gas Management – Comprehensive dissolved gas removal solutions to enhance product consistency and shelf life.

Process Filtration & Membrane Separation – Advanced filtration and membrane separation technologies (microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) for water purification and cosmetic formulations.

Optimize your cosmetic production and packaging with PTI Pacific’s 800 Series. Contact us today!

Dissolved Gas Management for Cosmetic Manufacturing

PTI Pacific specializes in precise, cost-effective dissolved gas control, optimizing process water, blending, and packaging for superior product quality and stability.

Production & Blending

✔ Preventing Oxidation – Removes oxygen to protect sensitive ingredients like vitamin C and essential oils from degradation.

✔ Ensuring Product Consistency – Eliminates air bubbles for a smooth, uniform texture in creams and lotions.

✔ Enhancing Mixing & Stability – Prevents gas interference for better ingredient dispersion and emulsification.

✔ Optimizing Filling Efficiency – Eliminates gas-related volume inaccuracies, reducing waste and ensuring precise filling.

Packaging & Finishing

✔ Preserving Product Integrity – Inert gas flushing prevents oxidation, extending shelf life.

✔ Minimizing Contamination Risks – Vacuum packaging reduces microbial growth, crucial for natural formulations.

✔ Enhancing Aesthetic Appeal – Prevents bubbles or separation, ensuring a pristine product appearance.

✔ Improving Dispensing Performance – Prevents air pockets in pumps and sprays for consistent, smooth application.

PTI Pacific’s advanced membrane technology ensures flawless cosmetic formulations—from production to final packaging. Contact us today!

Hygienic Membrane Solutions for Cosmetic Manufacturing

PTI Pacific’s advanced membrane technology ensures purity, safety, and efficiency in cosmetics production and packaging. Our Reverse Osmosis (RO), Nanofiltration (NF), Ultrafiltration (UF), and Microfiltration (MF) systems optimize water quality, ingredient processing, and product stability.

Key Applications:

✔ Reverse Osmosis (RO) – Delivers ultra-pure water, removing contaminants, minerals, and microorganisms for safe, high-quality formulations.

✔ Nanofiltration (NF) – Enhances active ingredients by selectively concentrating beneficial compounds while eliminating unwanted components, perfect for high-performance cosmetics.

✔ Ultrafiltration (UF) – Clarifies botanical extracts, removes particulates, and preserves proteins like collagen or elastin, maintaining efficacy.

✔ Microfiltration (MF) – Sterilizes and clarifies cosmetic formulations without heat, ensuring bacteria-free, shelf-stable products.

In Packaging:

✔ Sterile Environments – Supports contamination-free packaging, extending product shelf life.

✔ Quality Control – Ensures the highest purity in water and liquid ingredients for consistent, premium formulations.

PTI Pacific’s membrane solutions help cosmetic manufacturers achieve superior quality, purity, and efficiency. Contact us today!

Process Filtration Specialists

With over 30 years of combined process filtration experience, PTI Pacific is your best partner for everything winery filtration. From water filtration including media, carbon and membrane systems, to CIP recovery and ultra-pure water production, PTI Pacific can offer the perfect and most economical solution.

Water Filtration including Carbon, Media

Membrane systems for water and CIP recovery - MF, UF, NF, RO

Sartorius 12-inch and 16-inch Lenticular Filter Modules

Sartorius 400x400 and 600x600 Filter Sheets

Sartorius Premium Pleated Cartridges, Membrane and Capsule Filters

Integrity Testing Devices

Australia’s Largest Range of Stainless Steel Housings

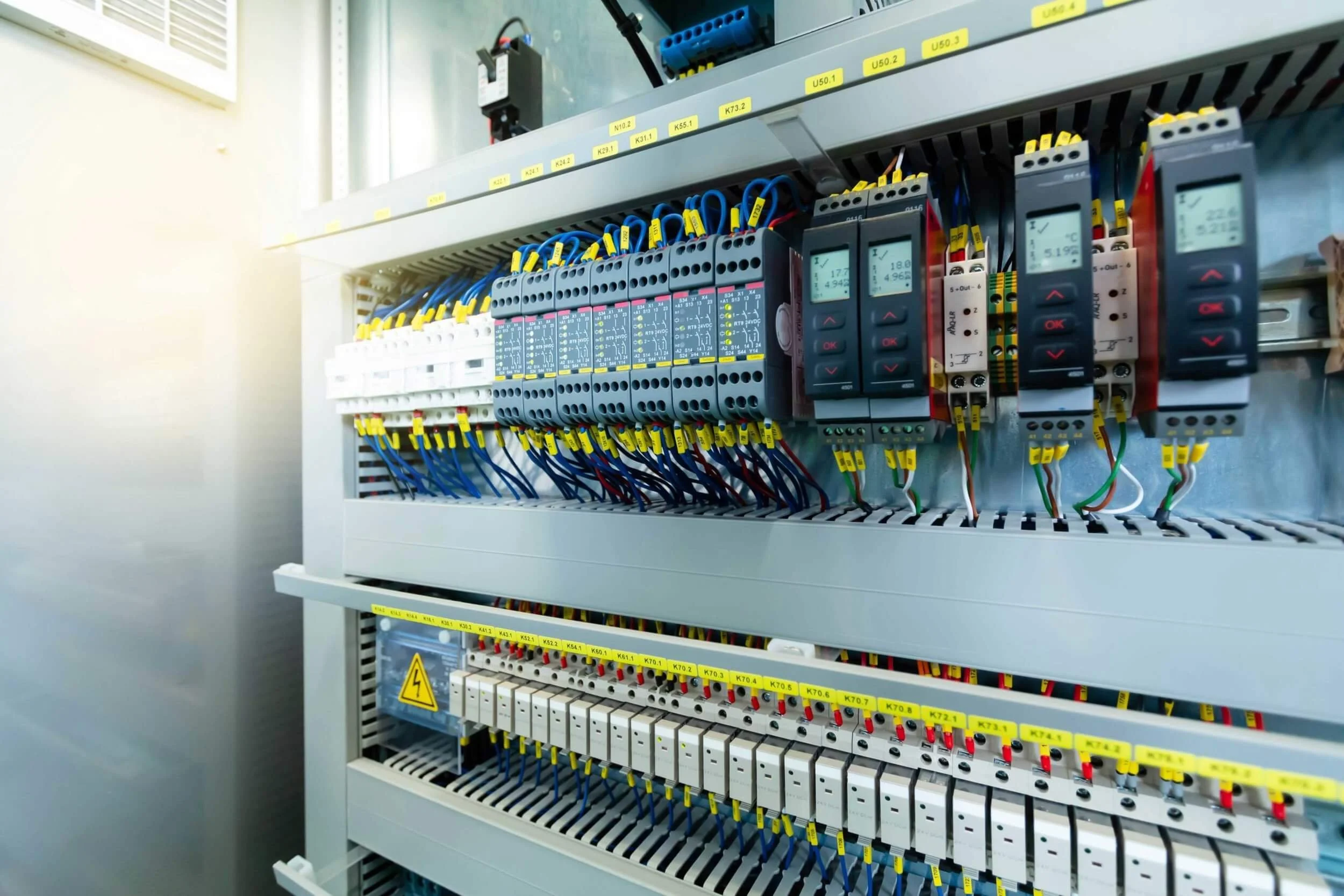

Automation & Mechanical Engineering

PTI Pacific has extensive experience in food production, cooking and processing through to packaging and as such are the perfect partner for your electrical and automation upgrades or projects. As controls specialists we can support your process facility with:

PLC and HMI Programming

Control Panel Building and Installation

Electrical drafting and design

Machine upgrades and automation

Automation and Controls for Pumps, Drives, Valves, Heat-Exchanger, Conveyors etc

Tank Temperature Control Systems

Remote Machine Assess and Telemetry

SCADA Programming and Development

In addition to Electrical and Automation, PTI Pacific can offer a suite of mechanical and project engineering solutions for any Food Manufacturing application. These include:

Machine and factory design, layouts, P&ID and process flow modelling

CAD design including Autocad and Solidworks 2D/3D modelling

Project management for new or upgrade process and packaging lines

Machine sourcing and procurement including importing, installation and commissioning

SOP and operations manual development and writing

Service and preventative maintenance support