Dairy Manufacturing

PTI Pacific is a 100% Australian owned company specialising in the design, engineering and manufacturing of high-quality machines and production solutions for Dairy Manufacturers.

CIP Solutions - Economical Automated Cleaning (CIP) solutions from single-tank mobile up to multi-vessel Hot Water and steam sterilising systems for small and medium process facilities

Water Treatment & Purification -PTI Pacific delivers premier water treatment technologies tailored for the food manufacturing sector. We prioritise water quality for compliance and product excellence, offering solutions from bespoke filtration to advanced and automated purification for all scales of operation, solutions including:

Mains Water Treatment - carbon treatment, particulate (including High-flow) cartridges and bag filters

UV disinfection& Ozonation

Turnkey membrane systems MF, UF, NF and low, high pressure plus industrial and hygienic membrane modules.

Sterilising filtration, including sterile water, tank venting and sterile air/gas

Refrigeration and Climate Management - PTI Pacific revolutionizes dairy production with advanced chilling systems tailored for the industry's unique needs. Our technology ensures precise temperature control, critical for dairy product quality and safety. Focused on energy efficiency, our chillers reduce costs and enhance productivity.

Our Most Popular Technologies for Dairy Manufacturers

Natural Shelf-Life Stabilization for Foods & Sauces

FoodCare® AMS & JMS – A label-friendly anti-microbial processing aid designed to protect against bacteria, mold, and yeast, increasing shelf life without preservatives.

Ideal for:

✔ Purées, sauces, and pastes (pasta sauce, ketchup, pesto, curry paste)

✔ Dips, salad dressings, jams, and marmalades

✔ Soups (tomato, leek & potato, mushroom, vegetable)

✔ Non-active yogurts, cheese, and cream cheeses

Key Benefits:

✔ Naturally derived acidulants for safe and effective microbial protection

✔ No synthetic preservatives

✔ No loss of taste, texture, or nutritional value

✔ Extends shelf life naturally

800 Series: Elevating Dairy Manufacturing with Advanced Filtration & CIP Solutions

The PTI Pacific 800 Series is a highly efficient solution designed to meet the stringent hygiene and operational demands of dairy manufacturing. Engineered for precision and reliability, this advanced system ensures superior cleanliness, optimized filtration, and seamless integration into dairy processing facilities. From milk and whey processing to cheese and yogurt production, the 800 Series enhances efficiency while maintaining the highest standards of food safety and product quality.

Key Benefits for Dairy Manufacturing

✔ Enhanced Hygiene and Product Safety – Effectively eliminates contaminants, bacteria, and residues, ensuring compliance with stringent food safety regulations.

✔ Automated Clean-in-Place (CIP) Efficiency – Reduces manual cleaning requirements, minimizes downtime, and extends equipment lifespan, leading to cost-effective operations.

✔ Optimized Filtration for Dairy Liquids – Maintains the integrity of milk, whey, and cream by preserving essential nutrients, flavors, and consistency.

✔ Reduced Water and Chemical Consumption – Advanced CIP technology lowers operational costs while supporting sustainable production practices.

✔ Seamless System Integration – Designed to work within existing dairy processing lines, improving workflow efficiency and reducing production bottlenecks.

Driving Excellence in Dairy Processing

Dairy production requires absolute cleanliness and process precision to prevent contamination, spoilage, and variations in product quality. The PTI Pacific 800 Series provides an industry-leading solution that enhances food safety, operational reliability, and production efficiency.

By integrating the 800 Series into dairy processing facilities, manufacturers can achieve consistent product quality, improved resource management, and optimized performance, ensuring a competitive edge in the dairy industry.

Process Filtration Specialists

With over 30 years of combined process filtration experience, PTI Pacific is your best partner for everything winery filtration. From water filtration including media, carbon and membrane systems, to CIP recovery and ultra-pure water production, PTI Pacific can offer the perfect and most economical solution.

Water Filtration including Carbon, Media

Membrane systems for water and CIP recovery - MF, UF, NF, RO

Sartorius 12-inch and 16-inch Lenticular Filter Modules

Sartorius 400x400 and 600x600 Filter Sheets

Sartorius Premium Pleated Cartridges, Membrane and Capsule Filters

Integrity Testing Devices

Australia’s Largest Range of Stainless Steel Housings

Hygienic Membrane Solutions for Dairy Processing

PTI Pacific provides hygienic turnkey solutions and membrane retrofitting designed to enhance dairy separation processes, ensuring efficiency, product quality, and sustainability. Our advanced membrane filtration technologies support a range of dairy applications, including:

Reverse Osmosis (RO): Used for milk concentration to enhance processing efficiency and water recycling & CIP recovery to reduce waste and operational costs.

Nanofiltration (NF): Optimized for whey demineralization to improve nutritional profiles and lactose concentration for ingredient production.

Ultrafiltration (UF): Ideal for milk protein concentration, whey protein concentration, and milk standardization, ensuring consistent product quality and improved yield.

Microfiltration (MF): Supports milk clarification, cheese brine purification, bacteria and microorganism reduction, milk fractionation, and protein standardization, contributing to extended shelf-life (ESL) milk and lactose reduction. MF is also essential for water filtration and RO pre-treatment, maintaining process hygiene and efficiency.

PTI Pacific’s membrane filtration solutions help dairy manufacturers improve product consistency, optimize ingredient recovery, and reduce environmental impact, ensuring the highest industry standards.

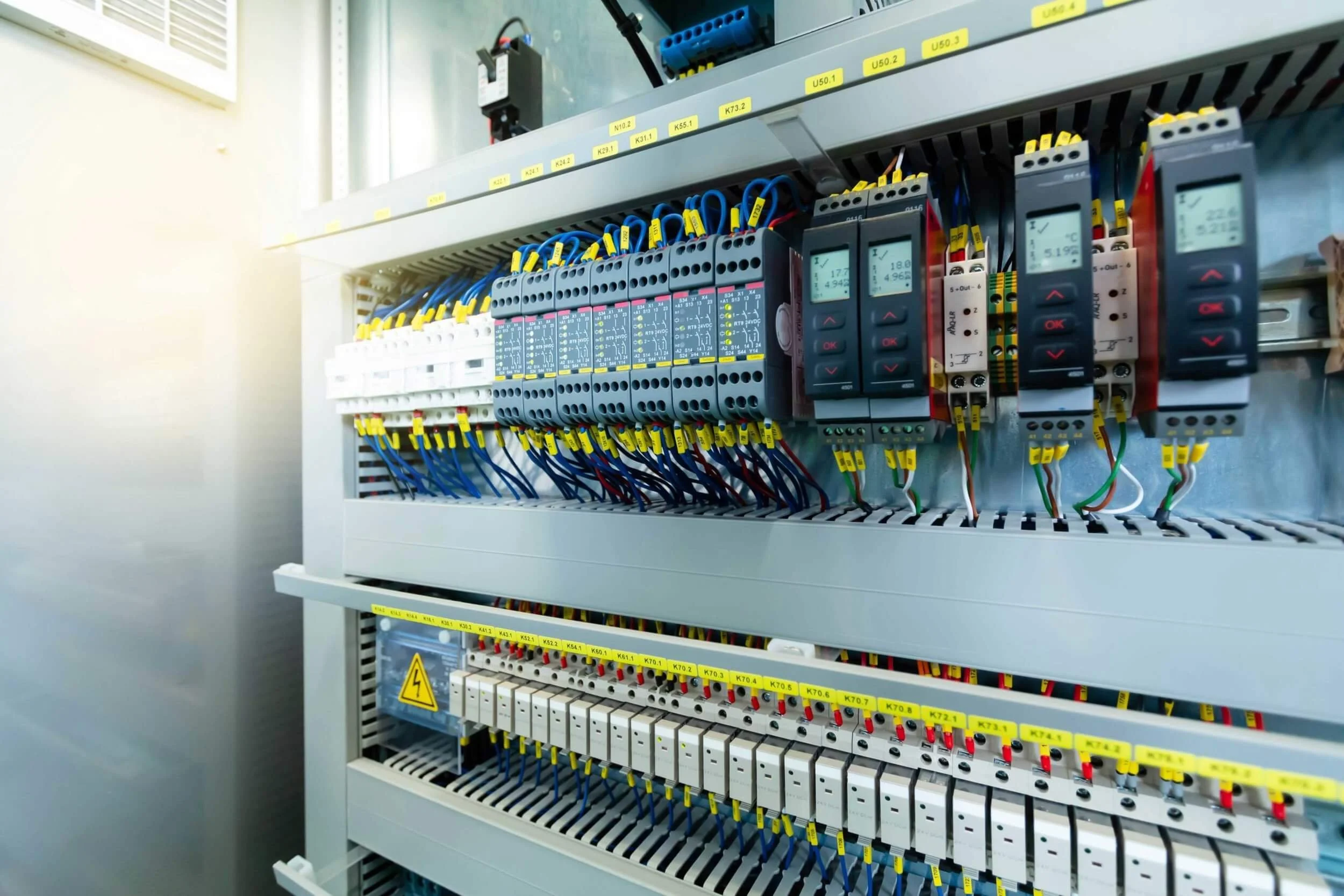

Dairy Manufacturing Automation & Mechanical Engineering

PTI Pacific has extensive experience in food production, cooking and processing through to packaging and as such are the perfect partner for your electrical and automation upgrades or projects. As controls specialists we can support your process facility with:

PLC and HMI Programming

Control Panel Building and Installation

Electrical drafting and design

Machine upgrades and automation

Automation and Controls for Pumps, Drives, Valves, Heat-Exchanger, Conveyors etc

Tank Temperature Control Systems

Remote Machine Assess and Telemetry

SCADA Programming and Development

In addition to Electrical and Automation, PTI Pacific can offer a suite of mechanical and project engineering solutions for any Food Manufacturing application. These include:

Machine and factory design, layouts, P&ID and process flow modelling

CAD design including Autocad and Solidworks 2D/3D modelling

Project management for new or upgrade process and packaging lines

Machine sourcing and procurement including importing, installation and commissioning

SOP and operations manual development and writing

Service and preventative maintenance support